How olive oil is made

Madrid |As we’ve already learned in our post How to use, buy, and store olive oil, olive oil should be thought of as the juice from a fruit. As with any other fruit, there needs to be a harvest as well as a process for extracting the juice from the fruit.

As a general rule, quality olive oils are harvested, extracted, and stored on the same day. This means that during the harvest season, usually between November and March, olive oil is produced every day.

Step 1 – the olive harvest

Firstly, a big mat is laid out under the tree to catch the olives. Workers then hit the branches with long poles to shake the fruit from the trees, or some use special heavy machinery that vibrates along the trees’ branches.

Once the olives and leaves have fallen onto the mat, they are collected and carried to the oil mill by a tractor.

You can watch some short videos about each stage of the process, from harvesting to collection, and unloading to transporting the olives.

Step 2 - extracting the oil

Once in the mill, the olives are washed to remove any dust or dirt from the harvest, collection, and transportation.

Once washed, the olives are separated from the stems and leaves. This process is manually supervised to ensure that no stones or rotten olives get into the mix.

Next, the olives are crushed in a hammer mill to produce smaller pieces of olive. These then go into a mixer to produce a paste which is then pumped into a decanter.

Finally, in the decanter the process of centrifuging is used to separate the oil from water and solid residue.

This physical process of crushing, mixing, and decanting impacts the temperature of the paste, which then triggers chemical reactions (oxidation). The oxidation must be controlled to ensure a higher quality oil – the term “cold press” comes from the fact that the temperature is kept below 25º C during the mixing process.

And then you have a fresh, fragrant olive juice that is almost ready to be enjoyed.

Just left is the filtering and storing of the olive oil in stainless steel vats, very much like the ones used in wineries.

Check out this video to see how the mixer works.

Step 3 - testing and analysis. Types of olive oil

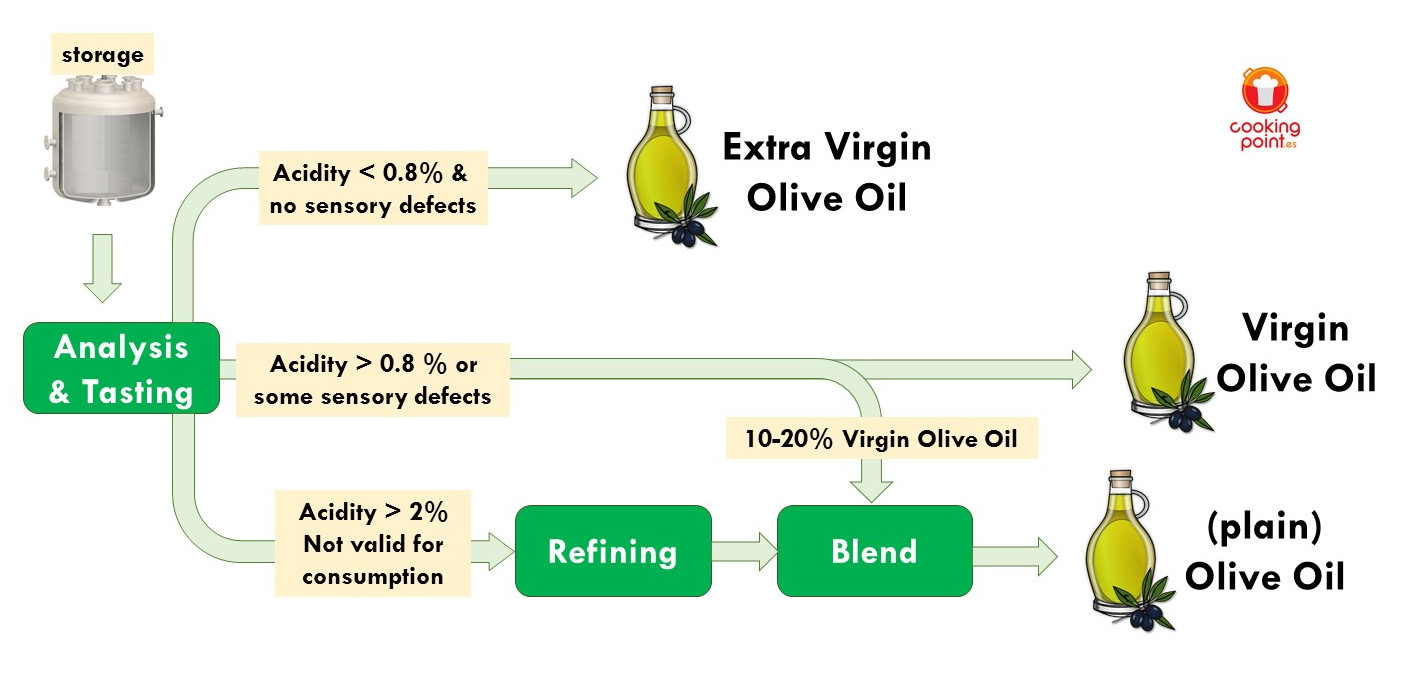

Once the oil has been extracted from the olives, it needs to be categorized. This involves two steps – a lab analysis and a sensory analysis. The lab analysis looks for the presence of chemical compounds in the oil, while the sensory analysis checks other features such as smell and taste.

The most important indicator resulting from the chemical test is acidity, which is measured in degrees and equates to the percentage of free fatty acids in the oil. The lower the acidity, the better, and for this reason extra virgin olive oil can’t exceed 0.8º acidity (0.8%). For the sensory test, the extra virgin olive oil must not have any defect in taste or aroma.

If the acidity is between 0.8º and 2º or the oil has few sensory defects, the oil will be categorized as virgin olive oil. That is, it is still a nice olive oil, but not as good as the extra virgin.

An oil with acidity higher than 2º or with severe taste defects will need to be refined to remove all defects – whether they are chemical or sensory. The result of the refining process is a liquid without color, smell, or taste. It is just plain transparent fat in liquid form. This fat is blended with a small portion (10-20%) of virgin olive oil to recover the color, taste, and aroma, which is then called plain olive oil.

In some markets there is still one more type of olive oil, called pomace olive oil, or more correctly speaking, olive pomace oil, which is considered the lowest quality of olive oil. Technically, it is not olive oil, as it is not extracted with a mechanical process (that is, not a juice of the olives), but from putting the residual paste from the decanter through a chemical process to obtain a liquid that, in turn, is refined and blended with virgin olive oil to get the pomace olive oil.

Note: This classification of olive oils is derived from the European Union, so it is applicable to all oils produced and marketed within the EU.

Related posts

Spain's Wine 101

Find out which are the most famous winemaking regions and wine types in Spain. This post will guide you to identify and drink the most genuine and typical ones from this country.

What is Iberico pig ham?

What makes so special the Iberico Ham? This particular breed, only found in Spain has unexpected benefits for your health

How to use, buy and store olive oil

Do you know when to use extra virgin olive oil instead of regular olive oil? Our practical guide will help you learn more about Spain's most famous export and improve your flavors in the kitchen